Before the complicated evolution of COVID-19 epidemic, medical masks became a familiar item in daily life and were bought by many people. However, not everyone knows how this face mask is structured and how it is produced. Let’s take a closer look at how the medical face mask production line works to increase your awareness about this health protection product, as well as know what kind of medical masks are. amount.

What is a medical mask?

Medical face mask is a specialized protective mask in the medical industry, used to cover the face area (usually the nose, mouth) to prevent and protect the wearer from being infected with bacteria and diseases, dust through inhalation. Medical masks are widely used in medical facilities, providing for doctors, nurses, nurses, forensic examiners … especially those doing surgical work. Medical masks are often indicated for use in the following cases:

- When there is a splash, splashes, or spraying of body fluids that carry bacteria, pathogens … affecting the surrounding.

- When near sources of body fluids from 1.5m or less.

- When working in an aseptic environment such as operating room, isolation room …

Medical face masks have three main effects: prevent dust, prevent chemicals (including car smoke) and prevent microorganisms.

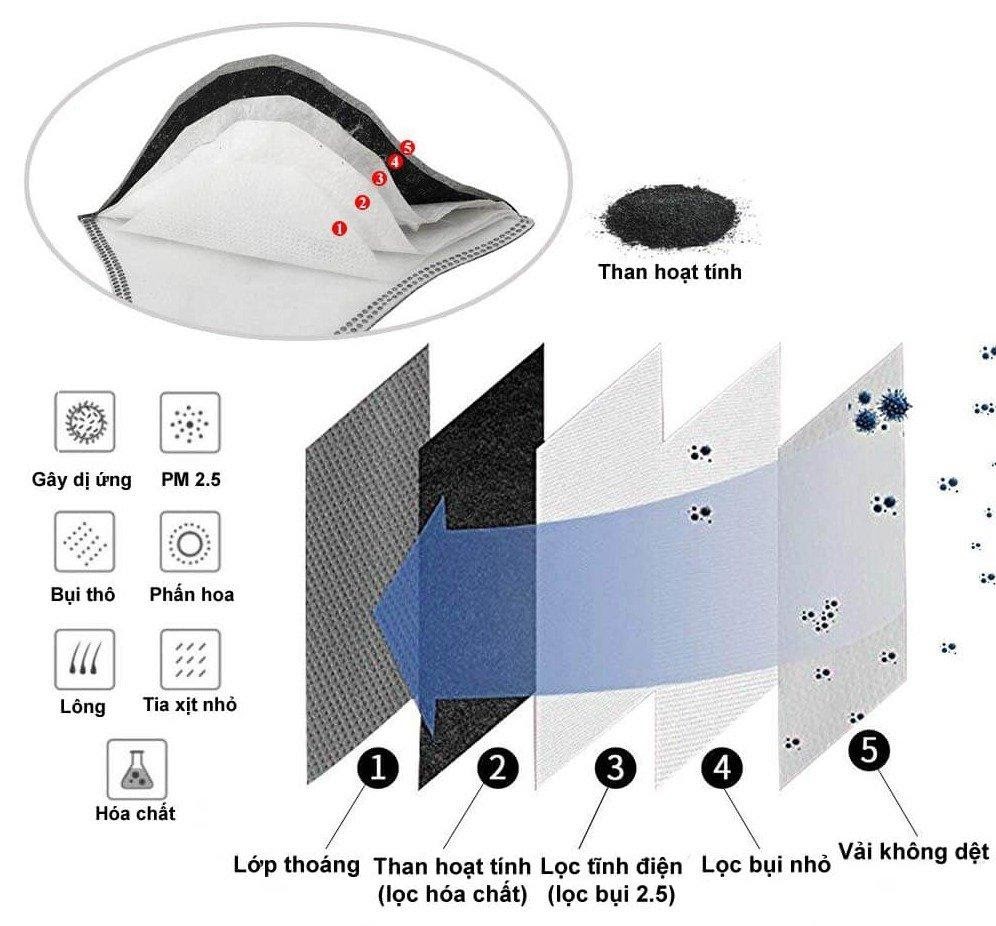

Materials for standard medical masks include: Non-woven fabric, antibacterial filter cloth, if the mask is an activated carbon medical mask, there will be an additional layer of activated carbon filter paper to help absorb gas, toxic gas in air, effectively prevent dirt, ensure safety for the respiratory system. These ingredients will be arranged in order by a standard medical mask export production line and sewn up into a complete mask. Specifically, how this chain works, we will find out in the next section of the article.

How does the medical mask production line work?

Standard medical face masks used in medical work usually have from 3 to 5 layers, including the main ingredients: the waterproof breathable non-woven fabric outside, the antibacterial filter cloth can have from 1 – 2 layers (including PM2.5 electrostatic dust filter and ordinary dust filter), activated carbon filter cloth (if any), finally a hygroscopic non-woven fabric layer to prevent secretions from the mouth, nose spread into the environment.

The medical mask fabric layers will be installed on the large rotating shaft on the medical mask making machine, then pulled in and arranged in order on a dedicated conveyor belt. Here, the strip of material will be passed through a part that helps create creases on the face of the mask, this fold has the effect of shrinking the mask’s size when in flat form and can be pulled out to adjust the size arbitrarily. according to each face.

In parallel with this process, a sewing machine adds a small metal bar to one end of the mask horizontally and stitches the edges horizontally. This metal piece works to keep the edges of the mask tightly around the bridge of the wearer’s nose, ensuring that secretions from the nose and mouth will not be able to shoot out as well as ensuring dirt, bacteria do not follow. nasal gap flying into the user’s mouth and nose.

After being pleated, strips of ingredients to make medical masks are pushed through a cutter. Here, the machine will cut this material strip into small masks according to the pre-installed size and push into the conveyor belt, delivered to the waiting sewing machines.

At the next stage in the medical mask production line, the mask, after being shaped and chopped, will be transferred to the edge stitching machines to process the sealing and add straps. The strap of the medical mask can be elastic or non-woven and can be stretched, adjusted to suit each different face.

The last stage in the manufacturing process of medical masks, the workers will put the specified number of masks into plastic bags and put them in paper boxes and pack according to set standards.